Essential Oil Production Methods: How Truly Great Oils are Made

The governing principle of production: Preserving all of the oil's therapeutic properties

More than just a commercial concern.

At dōTERRA®, the first concern is not the commercial aspects of marketing essential oils, but people. The men and women who founded the company came to respect the the many life-enhancing properties of the oils, and their love for the oils led them to search for the highest quality oils available. What they found surprised even them, and they fell in love with essential oils all over again.

“It was,” they said, “like discovering aromatherapy all over again.”

From its beginning, rather than defining the bottom line in purely monetary terms, ultimately sacrificing everything to that, dōTERRA® has made it its mission to offer only the finest quality oils, containing the most active, and widest array of therapeutic constituents possible, regardless of cost.

Sourcing from trusted producers: Where it all begins

While some essential oil companies emphasize the size of their farms and distilling operations, the truth is that, with essential oils, geography really matters. However great your production methods might be, if they are implemented in the wrong place, you will not end up with a truly great oil. Quality essential oils must be sourced from distillers who not only know how to do it right, but are situated where the highest quality materials can be grown, harvested and distilled.

At dōTERRA®, the sourcers use the knowledge they have gained, through their years of experience, to find the highest quality oils available anywhere. Working with trusted producers from around the world, every batch of oil is produced according to the highest standards and independently cross tested, using mass spectrometry and gas chromatography (and other methods, as needed), to ensure both extract purity and composition potency. This assures you that any of the dōTERRA® oils you buy are both free of contaminants and contain the active compounds, at the right levels, to guarantee safety and effectiveness.

dōTERRA® works closely with a global network of leading essential oil chemists and growers, to select botanicals of the correct species, grown in the ideal environments and carefully harvested at the right time. The aromatic compounds of the plants are skillfully extracted by experienced distillers and subjected to exacting chemical analysis, to ensure purity and composition. Because of this, dōTERRA‘s certified pure therapeutic-grade® (CPTG®) essential oils represent the safest and most beneficial oils available in the world today.

Equally stringent standards of safety and efficacy are applied to all of dōTERRA‘s Essential Wellness products. Guided by its Scientific Advisory Board, dōTERRA® uses only top development and manufacturing partners, who maintain GMP certification and enjoy industry reputation for superior innovation and quality. Each dōTERRA® product is guaranteed to exceed customer satisfaction and performance expectations.

Proper farming methods: a critical first step

The production of a great essential oil begins with growing high quality herbs for distillation.

On the farms, the species of herbs grown is carefully selected, making sure that only those cultivars that produce the highest quality essential oil are used. For example, the lavender must be the authentic Lavandula angustifolia, which yields an oil low in camphor and rich in lavendulol and lavendulol acetate (the constituents believed to be the key to lavender‘s therapeutic action).

These plants must then be grown in soil that is uncontaminated by chemical fertilizers, pesticides, fungicides or herbicides, and away from other pollution sources, and watered with pure water sources.

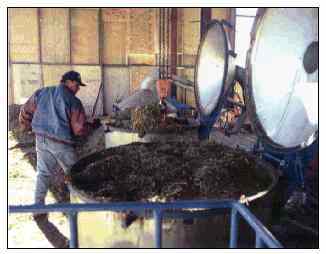

Distilling the oils: In the traditional way, to preserve the quality of the oil

To produce the highest quality essential oil, the herbs must be distilled fresh. This is critical to the production of the oils, because the essential oils in the plant materials are very volatile, and any delay in distilling them means that precious oil constituents are lost to evaporation.

Despite the cost, compared to the practices of commercial distillers, it is critical to take care to preserve all of the fragile aromatic constituents of its essential oils during the distillation process:

→ Plants are steam-distilled, in small batches for extended periods, using low pressure and low heat; the traditional method of distillation, used for centuries in Europe.

→ No solvents or synthetic chemicals of any kind are used or added in the distillation process.

→ The cookers are constructed from metals that will not react with the oils, chemically altering them and harming their therapeutic properties.

Independent analysis of the oils to assure you of top quality

When sourced, each batch of oil is analyzed at an independent laboratory, cross tested, using mass spectrometry and gas chromatography (and other advanced methods, as needed), to ensure both extract purity and composition potency.

No cutting corners to make oils more cheaply

Producing pure, therapeutic-grade essential oils is very costly. The methods required are time- and labor-intensive, and it often requires several hundred — or even thousands — of pounds of raw plant material to produce a single pound of essential oil. For example,

- it takes three tons of melissa to produce one pound of melissa oil. Its extremely low yield explains why it sells for $9000 to $15,000 per kilo.

- It takes 5,000 pounds of rose petals to produce one pound of rose oil.

It’s not hard to find cheaper essential oils, but you would have to travel the world over to find any that are even close to the quality of dōTERRA®.